Streamlining Inventory: Boosting Efficiency

In today’s fast-paced business world, the key to success lies in the ability to streamline inventory and boost efficiency. With the rise of e-commerce and the increasing demands of customers for quick delivery times, businesses must find ways to optimize their inventory management processes to stay competitive in the market.

One of the most practical strategies for success in cutting down on excess inventory is to streamline the inventory management process. This involves carefully analyzing the current inventory levels, identifying slow-moving or obsolete items, and implementing strategies to reduce excess stock. By streamlining the inventory, businesses can improve efficiency, reduce costs, and increase profitability.

There are several ways to streamline inventory and boost efficiency. One effective strategy is to implement a just-in-time inventory system, where inventory is only ordered and received when it is needed. This helps to reduce excess stock and minimize storage costs. Additionally, implementing an automated inventory management system can help to streamline the process of tracking and managing inventory levels, ensuring that stock is always available when needed.

Another key strategy for streamlining inventory is to optimize the supply chain. By working closely with suppliers to improve lead times and reduce order quantities, businesses can minimize excess inventory and improve overall efficiency. Collaborating with suppliers to implement vendor-managed inventory systems can also help to streamline the inventory management process and ensure that stock levels are always optimized.

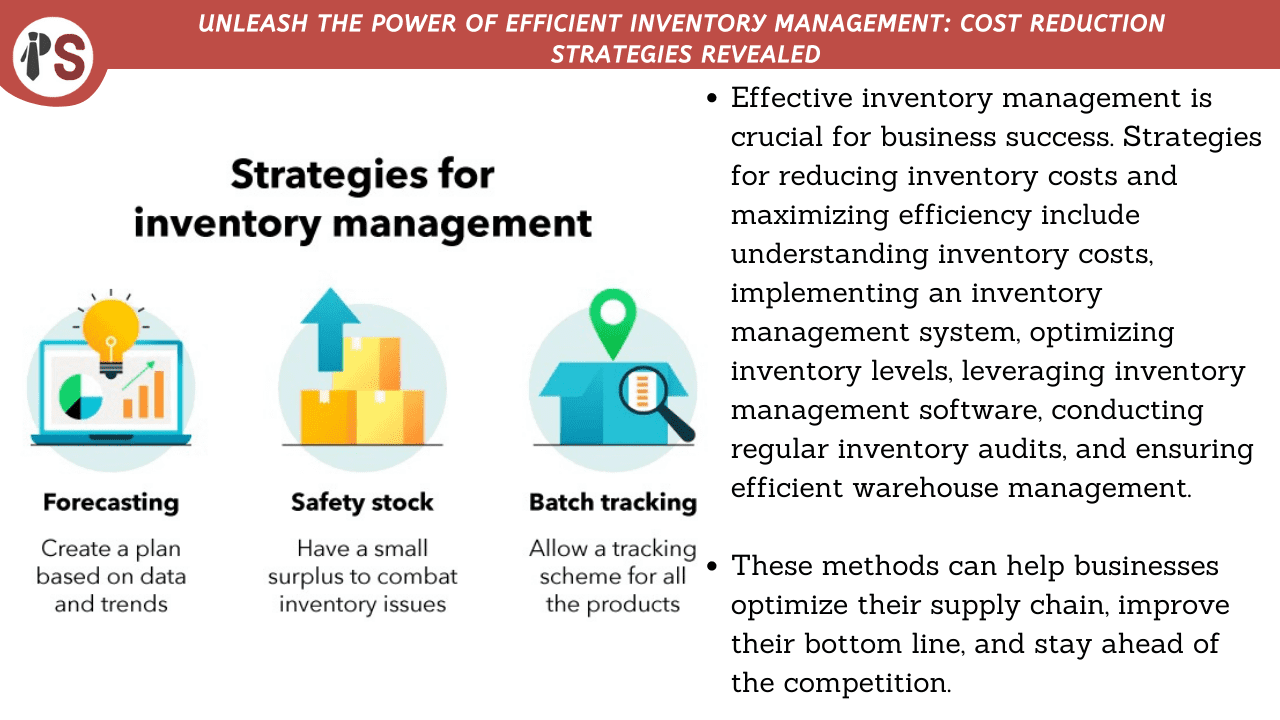

Image Source: professionalsaathi.com

In addition to optimizing the supply chain, businesses can also streamline inventory by implementing demand forecasting techniques. By analyzing historical sales data and market trends, businesses can more accurately predict future demand and adjust inventory levels accordingly. This can help to reduce the risk of excess inventory and ensure that stock levels are always aligned with customer demand.

Furthermore, businesses can streamline inventory by implementing efficient warehouse management practices. This includes organizing the warehouse layout for maximum efficiency, implementing barcode scanning and RFID technology for accurate tracking of inventory, and implementing real-time inventory monitoring systems to ensure that stock levels are always up to date.

Overall, streamlining inventory and boosting efficiency is essential for success in today’s competitive business environment. By implementing practical strategies such as just-in-time inventory systems, optimizing the supply chain, implementing demand forecasting techniques, and improving warehouse management practices, businesses can reduce excess inventory, minimize costs, and increase profitability. With a focus on efficiency and optimization, businesses can stay ahead of the competition and thrive in the ever-changing market landscape.

Mastering the Art of Inventory Reduction

In the fast-paced world of business, excess inventory can be a major headache for companies of all sizes. Not only does excess inventory tie up valuable resources, but it can also lead to increased storage costs, decreased cash flow, and ultimately lower profitability. That’s why mastering the art of inventory reduction is crucial for any successful business looking to streamline operations and maximize efficiency.

One practical strategy for cutting down on excess inventory is to implement a just-in-time inventory management system. This approach involves ordering and receiving inventory only when it is needed, eliminating the need for large stockpiles of excess goods. By closely monitoring sales trends and demand forecasts, companies can ensure they have just enough inventory on hand to meet customer needs without overstocking.

Another effective strategy for reducing excess inventory is to closely collaborate with suppliers to establish lean inventory practices. By working closely with suppliers to streamline ordering processes and reduce lead times, companies can minimize the risk of overstocking and ensure a steady supply of goods without unnecessary excess inventory.

Additionally, conducting regular inventory audits and implementing strict inventory control measures can help companies identify and eliminate excess inventory quickly and efficiently. By closely monitoring inventory levels, identifying slow-moving or obsolete items, and implementing strategies to sell or dispose of excess inventory, companies can prevent excess inventory from accumulating in the first place.

Furthermore, embracing technology can also play a crucial role in mastering the art of inventory reduction. Inventory management software and systems can provide real-time visibility into inventory levels, sales data, and demand forecasts, allowing companies to make informed decisions about inventory levels and reduce the risk of overstocking.

In conclusion, mastering the art of inventory reduction is a crucial step for any business looking to streamline operations, boost efficiency, and maximize profitability. By implementing just-in-time inventory management, collaborating with suppliers, conducting regular inventory audits, and leveraging technology, companies can effectively cut down on excess inventory and achieve success in today’s competitive business environment.

How to Reduce Excess Inventory: Tips and Techniques