Dive into Efficiency: Just-In-Time Inventory Management

Just-In-Time (JIT) inventory management is a strategy that focuses on improving efficiency by only ordering and receiving inventory as it is needed in the production process. This approach helps businesses minimize waste, reduce carrying costs, and improve overall operational efficiency. By implementing JIT inventory management, businesses can streamline their processes and operate more effectively in today’s fast-paced and competitive business environment.

One of the key benefits of JIT inventory management is the reduction of excess inventory. Traditional inventory management models often result in businesses holding onto large amounts of inventory to account for fluctuations in demand or production delays. This excess inventory ties up valuable capital and takes up valuable warehouse space. With JIT inventory management, businesses can order inventory in smaller, more frequent batches, reducing the need for excess inventory and freeing up capital for other investments.

Another advantage of JIT inventory management is the reduction of carrying costs. Carrying costs include expenses such as storage, insurance, and depreciation of inventory. By minimizing the amount of inventory held on hand, businesses can reduce these carrying costs and improve their bottom line. Additionally, JIT inventory management can help businesses avoid obsolescence by ensuring that inventory is used or sold before it becomes outdated.

In addition to reducing waste and carrying costs, JIT inventory management can also lead to improvements in production efficiency. By ordering inventory only as it is needed, businesses can reduce lead times and respond more quickly to changes in demand. This can help businesses improve customer satisfaction and maintain a competitive edge in the market.

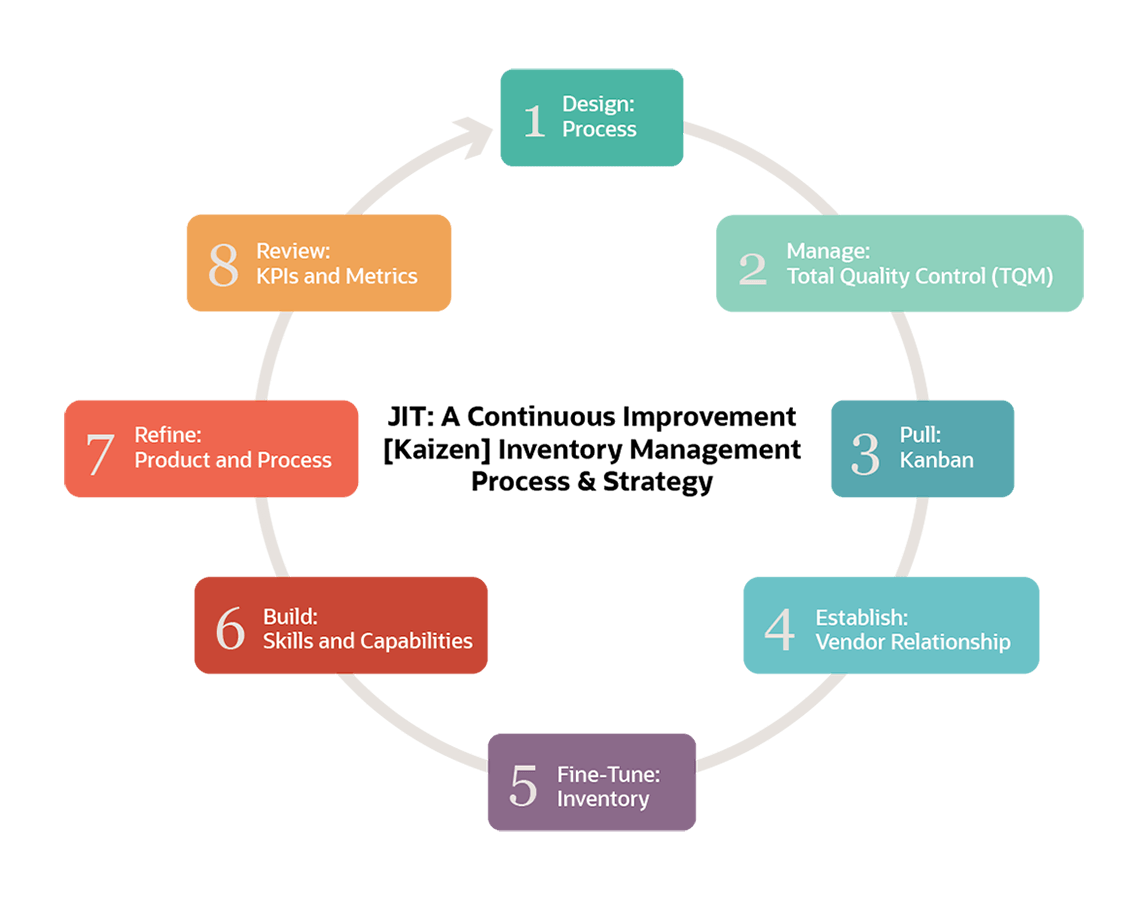

Image Source: netsuite.com

Implementing JIT inventory management requires careful planning and coordination between suppliers, production teams, and other key stakeholders. Businesses must work closely with suppliers to ensure that inventory is delivered on time and in the right quantities. Production teams must also be able to adapt to changes in inventory levels and production schedules to ensure that products are made efficiently and on time.

One challenge of JIT inventory management is the need for accurate demand forecasting. Businesses must be able to predict demand for their products accurately to avoid stockouts or delays in production. To address this challenge, businesses can use data analytics and forecasting tools to analyze past sales data and market trends, helping them make more informed decisions about inventory levels and production schedules.

Overall, Just-In-Time inventory management is a powerful strategy for businesses looking to improve efficiency, reduce waste, and stay competitive in today’s fast-paced business environment. By focusing on ordering and receiving inventory only as it is needed, businesses can streamline their processes, reduce carrying costs, and improve production efficiency. With careful planning and coordination, businesses can successfully implement JIT inventory management and reap the benefits of a more efficient and responsive supply chain.

Simplify Your Stock: A Beginner’s Guide to JIT Inventory

Welcome to the world of Just-In-Time (JIT) inventory management! If you’re looking to streamline your stock and improve efficiency in your business, then you’ve come to the right place. In this beginner’s guide, we’ll walk you through the basics of JIT inventory management and how you can simplify your stock to maximize your profits.

First things first, what exactly is JIT inventory management? Simply put, JIT is a strategy that aims to minimize inventory levels by only ordering and receiving goods as they are needed in the production process. This means that you won’t have excess inventory sitting around, tying up your resources and taking up valuable warehouse space.

One of the key principles of JIT inventory management is to reduce waste. By only ordering what you need, when you need it, you can minimize the risk of overstocking and reduce the chances of obsolete or expired inventory. This can lead to significant cost savings and improved cash flow for your business.

To get started with JIT inventory management, the first step is to analyze your current inventory levels and identify any areas of waste or inefficiency. Take a look at your sales data and forecast demand for your products to determine the optimal order quantities and reorder points. By aligning your inventory levels with customer demand, you can ensure that you always have the right amount of stock on hand.

Next, consider implementing a just-in-time ordering system with your suppliers. This means that you will only place orders for new inventory once your current stock has been depleted. By working closely with your suppliers and establishing strong relationships, you can ensure that your orders are fulfilled quickly and accurately.

Another important aspect of JIT inventory management is to focus on quality control. Since you will be receiving goods on a just-in-time basis, it’s crucial to have strict quality control measures in place to ensure that the products meet your standards. By maintaining high quality standards, you can prevent defects and rework, which can lead to costly delays and disruptions in your production process.

In addition to reducing waste and improving efficiency, JIT inventory management can also help to improve customer satisfaction. By having the right products available when your customers need them, you can reduce lead times and minimize the risk of stockouts. This can lead to higher customer loyalty and repeat business, ultimately driving growth and profitability for your business.

As you begin to implement JIT inventory management in your business, it’s important to continuously monitor and adjust your processes to ensure optimal performance. Keep track of your inventory levels, order lead times, and supplier performance to identify any areas for improvement. By continuously refining your processes, you can achieve greater efficiency and effectiveness in your inventory management practices.

In conclusion, JIT inventory management is a powerful strategy for simplifying your stock and improving efficiency in your business. By focusing on reducing waste, optimizing order quantities, and maintaining quality control, you can streamline your inventory processes and drive profitability. So why wait? Get started with JIT inventory management today and take your business to the next level!

A Beginner’s Guide to Just-In-Time Inventory Management